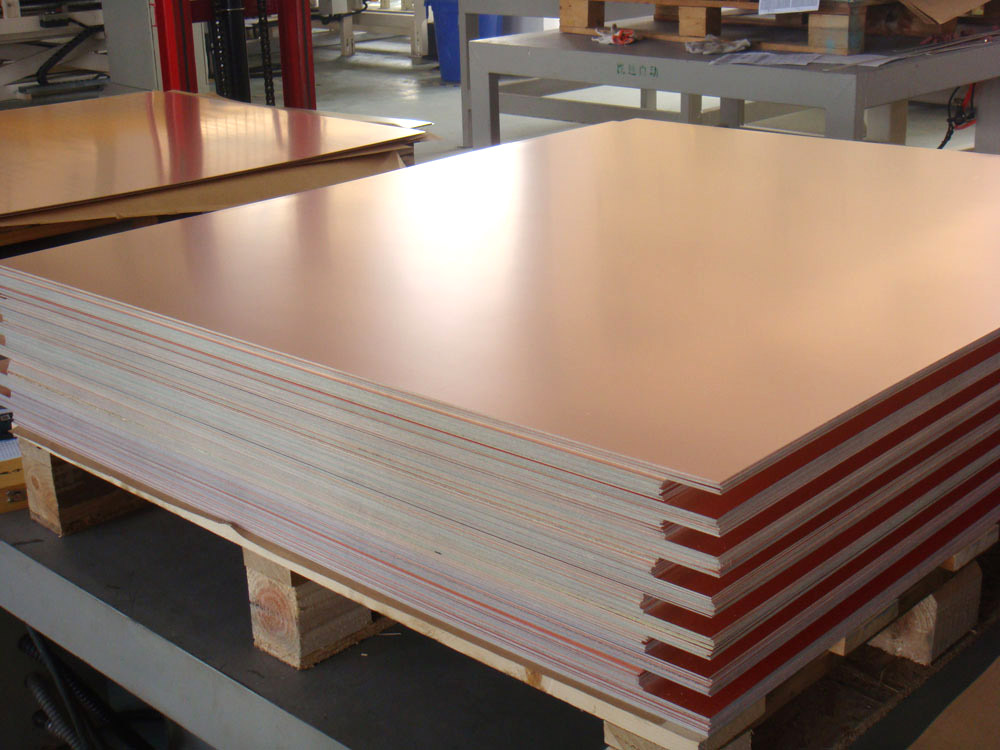

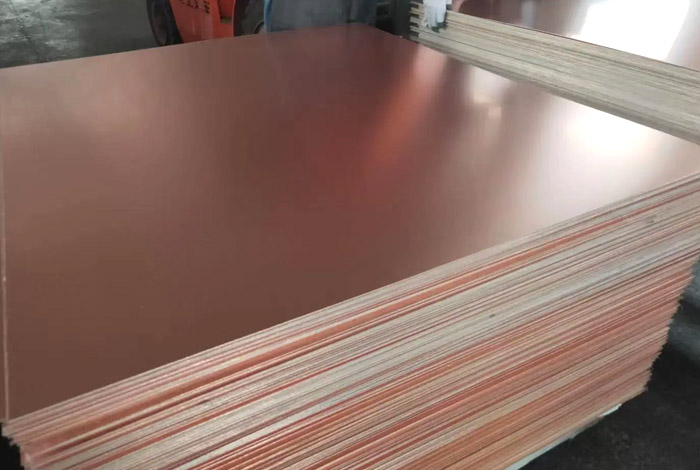

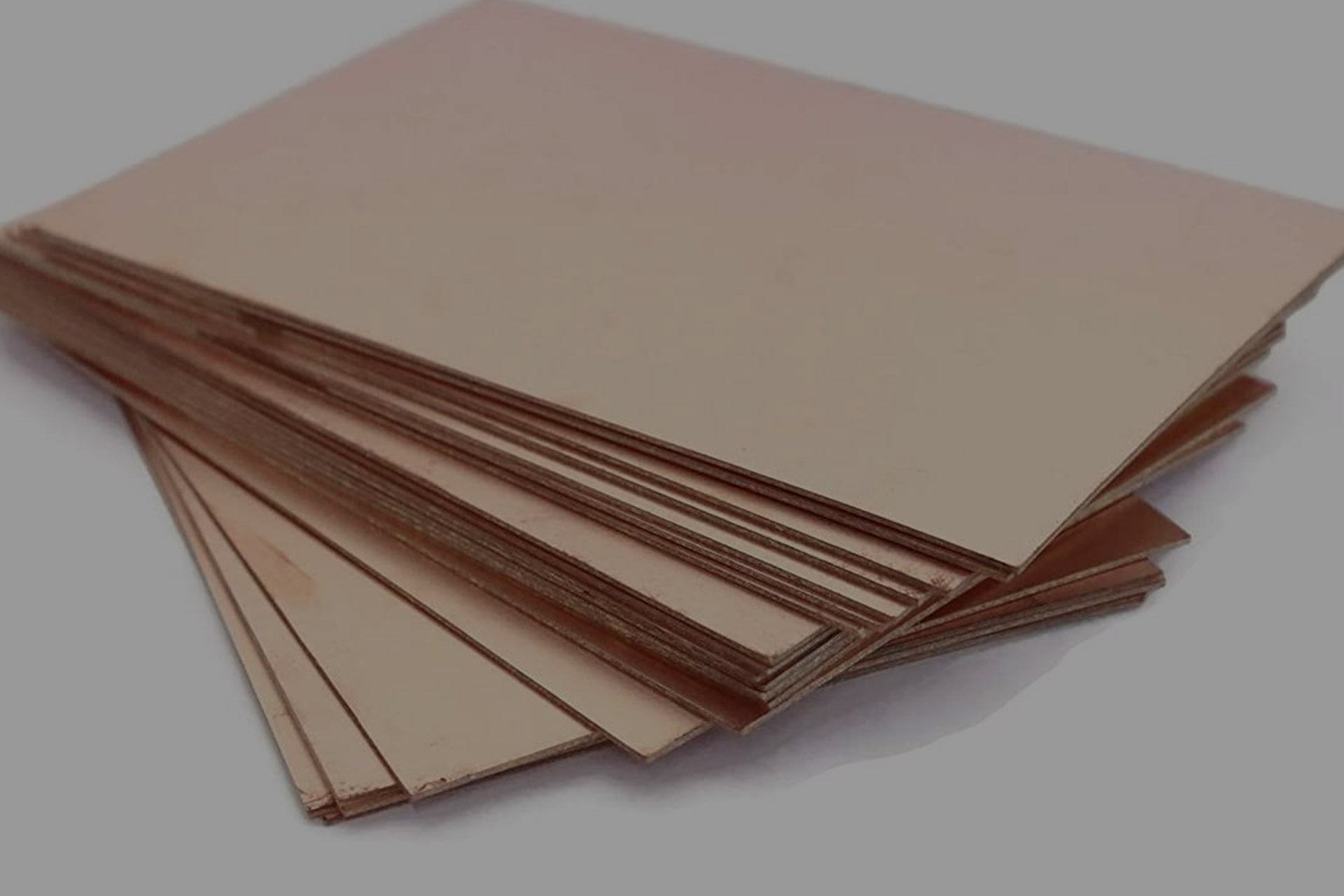

CCL is also known as substrate.

The reinforcing material is impregnated with resin, coated with copper foil on one or both sides, and a plate-like material made by hot pressing is called copper clad laminate (CCL). It is the basicmaterial to do PCB, often called the substrate. When it is used for multi-layer board production, also known as core board (core).

For CCL type, often according to different rules, there are different categories:

Mechanical rigidity of CCL: rigid CCL (FR-4, CEM-1, etc.) and flexible CCL (FCCL, FPC, etc.). (FR-4, CEM-3, etc.), metal-based CCL (aluminium plate, etc.), ceramic-based CCL (ceramic-based), according to different insulation materials and structure.

According to the thickness of copper cladding: divided into conventional and thin plate.

5mmConventional plate thickness ≥ 0.5mm

Thin plate thickness < 0.5mm (excluding copper foil thickness)

In accordance with UL standards (UL94, UL746E, etc.) flame retardant grades are non-flame

retardant Type (HB, etc.) and flame retardant CCL (FR-4, CEM-1, FR-1, CEM-3) and

According to some special performance of CCL:

Such as: high Tg plate (Tg> 170 ℃), medium Tg plate (Tg> 150 ℃), high dielectricity,High Dk, High CTI Plate, Low Thermal Expansion Coefficient Plate (Low CTE), Halogen-free plate (HF) and

so on. The composition of CCL

Production technology process of FR - 4 copper clad laminate

CCL performance and standardCCL performance requirements can be summarized as the following six aspects.metal foil surface pits, scratches, resin, fold, pinhole, bubbles, white wire, etc.

Size requirementSuch as: length, width, diagonal deviation, warping, etc.

Electrical performance requirementsIncluding the dielectric constant (Dk), dielectric loss tangent (Df), volume resistance, surfaceresistance, insulation resistance, arc resistance, dielectric breakdown voltage, electrical strength, compared to the tracking index (CTI), ion Migration (CAF) and so on.

Physical performance requirementsIncluding: dimensional stability, peel strength (PS), bending strength, heat resistance (thermalstress, Td, T260, T288, T300), punching, etc.

Chemical performance requirementsIncluding: flammability, weldability, chemical resistance, glass transition temperature (Tg), Z-axisthermal expansion coefficient (Z-CTE), dimensional stability and so on.

Environmental performance requirementsInclude: water imbibition, pressure vessels cooking test, etc.

Copper-clad laminate standard: IPC - 4101 - c

Copper-clad testing standard: IPC - TM – 650

OUR STANDARD SIZE IS 41*49 INCHES

WE ARE OM TRADINGImporter of Copper Clad Laminates

WE ARE OM TRADINGImporter of Copper Clad Laminates WE ARE IMPORTERImporter of Copper Clad Laminates

WE ARE IMPORTERImporter of Copper Clad Laminates WE ARE THE BESTImporter of Copper Clad Laminates

WE ARE THE BESTImporter of Copper Clad Laminates